Four-step forging technology continues to provide high-quality battery for users around the world

Grid is an important core component of lead-acid battery.the electrical conductivity,corrosion resistance and consistency of grid have an important influence on the dynamic performance,life and stability of lead-acid battery.

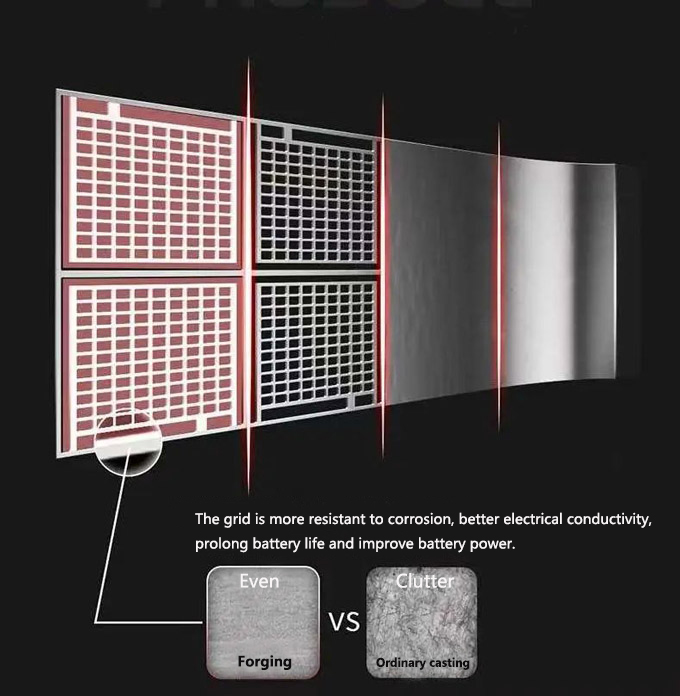

In the past,the grid was melted into lead liquid through lead ingots,and the lead liquid was poured into the grid mold with grid cavity and formed after cooling,which is referred to as"gravity casting".The grid manufactured by this method is prone to uneven thickness of grid bars,even pores,slag inclusion and other defects,which seriously affect the performance of the battery,and the production efficiency is low,which can not meet the growing production demand.Therefore,it is particularly important to solve this kind of problems.

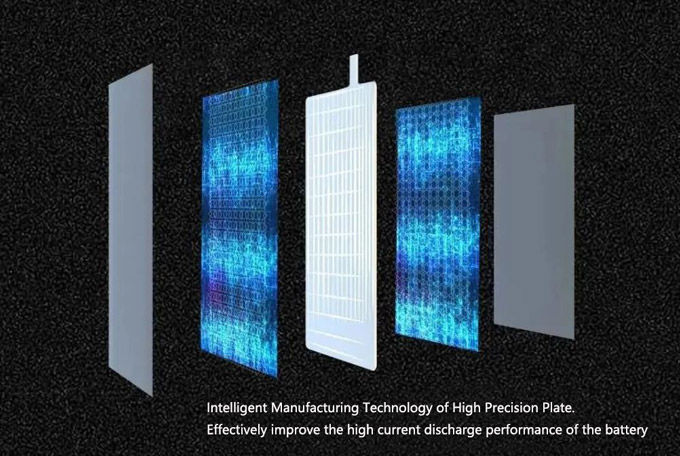

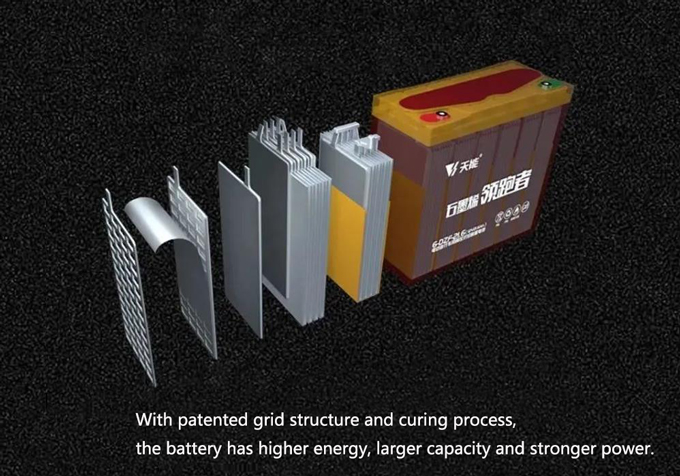

In view of the weak points of these technologies,Tianneng researched and invented a grid continuous casting and rolling device,which melts lead ingots into liquid lead,which is made into 20mm thick lead strip.Through 6 rolls,the thick lead strip of 20mm is rolled into a thin lead strip with very dense metallography on the right side of 1mm.The thin lead strip is then punched out of the plate grid belt by a high-speed punch,and then coated with lead paste,which is an active material for storing electricity,to make a plate,referred to as"four continuous forging".Through 6 rolls,20mm thick lead strip is rolled into 1mm thin lead strip,which solves the defects of porosity and slag inclusion.The grid blanked by high-speed punch has high precision,uniform thickness,more uniform corrosion resistance,and more bars along the conductive direction,which is more conducive to conductive.Four continuous forging solves the weak point of gravity casting and greatly improves the production efficiency.

The plate produced by centralized lead supply process"four continuous forging"has compact metallography,good corrosion resistance,uniform steel bar thickness,more uniform corrosion resistance,more uniform electrical conductivity,more uniform active material,more stable structure,more conductive directional bars and stronger electrical conductivity.it improves the comprehensive performance of the battery,and the continuous casting and rolling technology is one of the key technologies to improve the performance of the battery.

Due to the high degree of mechanical automation,the parameter error of the continuous casting and rolling grid is small,which is reflected in the good consistency of the plate,so it reduces the reaction imbalance caused by the consistency of the grid itself,reduces the concentration polarization and ohmic internal resistance in the reaction process,makes the electrode reaction more balanced,and greatly reduces the lagging ratio of the battery group,so as to improve the corrosion resistance and consistency of the battery.

In 2015,Tianneng established the first fully automatic production line of"continuous casting,rolling,punching and coating"in China,and was the first enterprise in the same industry to introduce the automatic production line of"continuous casting,rolling,stamping and coating"in the same industry,and achieved success in its overall promotion in the group.once again lead the new technological revolution in the green and low-carbon production of lead batteries.

At present,the 16th National Congress of Tianneng has realized the basic coverage of the automatic production line of"continuous casting,continuous rolling,continuous stamping and coating".With the continuous breakthrough and guidance of key technologies,Tianneng will continue to output high-quality power batteries for global users,making green and low-carbon travel a new fashion around the world.